| PRODUCTION OF DEVICES |

|

|

|

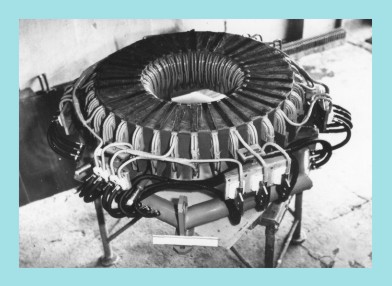

Flat induction MHD pump |

1.2. MHD mixers for electrically conducting melts

Objectives of action upon melt: homogenization and thermostatic control of mixtures, dissolution of additives.

Method of action: generation of volumetric azimuthal force acting upon melt due to interaction between a rotating magnetic field and the currents induced in a conducting medium.

- 1.3. Various MHD devices

for interaction on liquid metals.

|

|

Advantages relevant for various applications:

large starting and dynamo torque values, high stability under changing load conditions, since shafts are equipped with gaskets it is easy to achieve hermetic operation conditions.

Most efficient application areas of EEM:

high-power fans, pumps, disintegrators, crushers, mills, mixers, refiners, homogenizers, phase advancing transformers.

EEM application areas and technologies:

mixing, refining and pumping of liquid materials, including oil transportation and processing, as well as food industry;

pre-processing of agricultural products,

waste processing, e.g., in timber, glass industries.

|

|

EMP-mixer (One of the device modifications employed in photochemical industry)

|

|

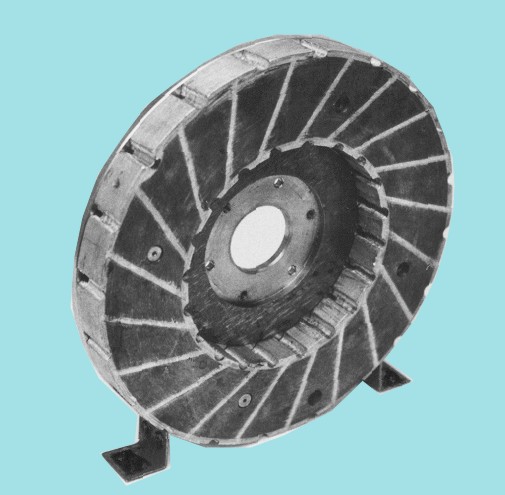

An inductor and one of the versions of a flat angular rotor of an experimental heavy-duty (equipped with water -cooled windings) asynchronous EEM, 1 m in diameter with dismantled operational element and casings.

Asynchronous

EEM of this type can be efficiently used:

In comparison

with regular electric motors EEM of this type offers the following advantages: